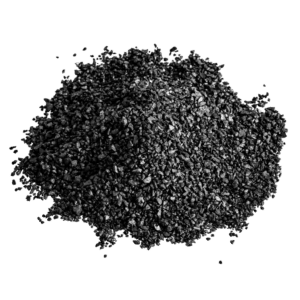

Activated carbon, also known as activated charcoal, is a highly porous carbonaceous material characterized by a large surface area and an extensive network of pores. It is produced by activating carbon-rich substances, such as wood, peat, coconut shells, or sawdust, through processes involving high temperatures and controlled oxidizing gases. The resulting material possesses a unique structure that enhances its adsorption capabilities.

Activated carbon aids in the degradation of contaminants primarily through the process of adsorption. Adsorption is the adhesion of molecules or ions to the surface of a solid substance, in this case, the activated carbon. The high porosity and large surface area of activated carbon provide numerous binding sites for contaminants to adhere to, effectively removing them from the surrounding environment.

Activated carbon’s effectiveness in contaminant degradation lies in its ability to attract and retain various pollutants, including organic compounds, volatile organic compounds (VOCs), and certain inorganic substances. This makes activated carbon versatile and widely used in water and air treatment processes.

In water treatment, activated carbon can be employed to remove organic pollutants, pesticides, and industrial chemicals. As water passes through a bed of activated carbon, the contaminants are adsorbed onto the carbon surface, leading to water purification. Additionally, activated carbon can be used in point-of-use filters or integrated into treatment plants to enhance the overall quality of drinking water.

The versatility and efficacy of activated carbon in contaminant degradation make it a valuable tool in environmental remediation and pollution control efforts across various industries. RPI continues to explore and optimize the application of activated carbon in innovative ways to address emerging environmental challenges.